DCA

DCA Manufacturing Case Study by Exact MAX ERP

The Company: About DCA

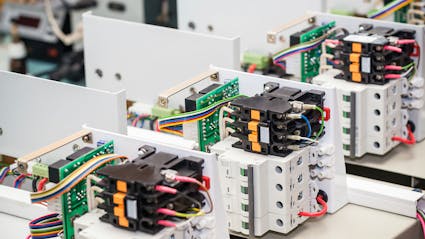

DCA is a quality and customer service-oriented subcontractor providing complex custom electronic and electromechanical assemblies to Original Equipment Manufacturers. Located in western Wisconsin, DCA specializes in the assembly and testing of small to mid-size, high-mix custom electronic devices, providing a full range of services from component procurement and engineering prototypes to system configuration and final customer warranty support.

The Situation: Data Integration

The Solution: MAX ERP

Exact MAX is a client/server application built to support discrete and repetitive manufacturing environments. Exact Synergy provides a Web-based Business Process Management solution that connects the people, processes, and knowledge that matter most to businesses. DCA looks to ExactMAX and Exact Synergy to replace divergent business systems and improve communications.

Despite the success DCA enjoyed with MAX, there were lingering challenges to its front office. Even though DCA used an account management customer service model, the company felt that providing the kind of superior service that separated it from its competitors required a level of information sharing that was difficult to manage with traditional business tools like e‑mail and voice mail. Critical customer information was locked away on personal network drives, in e‑mail accounts, or even in the account manager’s head. DCA needed to find a way to ensure that the latest customer information would be accessible to the right people at the right time.

The Results: MAX ERP System Implementation Benefits

Without a cohesive data management structure in place, any company will face difficult challenges that might inhibit growth and ultimately prevent success. Exact MAX and Exact Synergy can make many of those challenges more manageable, and their integrated capabilities have proven to be effective for DCA.

Additional MAX ERP Case Studies

Below, you can explore additional ERP case studies, showcasing companies that have reaped significant benefits from successful ERP implementations of MAX ERP.

Additional Industrial Machinery and Equipment Industry Case Studies

Explore additional case studies below, featuring companies in the Industrial Machinery and Equipment Industry. Also, see our comprehensive side-by-side comparison of all ERP systems for the Industrial Machinery and Equipment industry.

- M & T Machine ERP Case Study

- ACP Solutions ERP Case Study

- TrafFix Devices, Inc. ERP Case Study

- Stolle Machinery Designs ERP Case Study

- Merritt Trailers Inc. ERP Case Study

- ACE Designers Limited ERP Case Study

- BRAND ERP Case Study

- Roberts Precision Machine ERP Case Study

- First Tool Corporation ERP Case Study

- Radwell International ERP Case Study

- LH Industrial Supplies ERP Case Study

- Wisco Industries ERP Case Study

- Metform International Ltd. ERP Case Study

- Heinzen Manufacturing International ERP Case Study

- Farason ERP Case Study

- EAGLE Technologies Group ERP Case Study

- The Industrials Control Company ERP Case Study

- Hinds-Bock ERP Case Study

- Fullerton Tool Company ERP Case Study

- Frontier Oil Tools ERP Case Study

- Consarc ERP Case Study

- American Crane & Equipment Corp. ERP Case Study

- Campbell Wrapper Corporation ERP Case Study

- H&R Manufacturing and Supply ERP Case Study

- BendPak Inc. ERP Case Study

- Silex Innovations, Inc. ERP Case Study

- J.C. Steele & Sons ERP Case Study

- Glidepath ERP Case Study

Still seeking industry-specific information? Compare the top ERP software for the Industrial Machinery and Equipment Industry to find the product that best meets your company's needs and budget.